Professional Mobile Welding for Custom Metalwork and Fabrication

Reliable on-site welding and metalwork solutions for diverse projects

Understanding Mobile Welding and Custom Fabrication

Mobile welding involves bringing specialized welding equipment directly to the worksite, allowing for on-site metal repairs, assembly, and fabrication. Custom fabrication refers to the process of designing, cutting, shaping, and assembling metal components to meet unique project requirements. At Premier Arc Services, our mobile welding services combine these processes to deliver versatile solutions across various structural and metalwork needs.

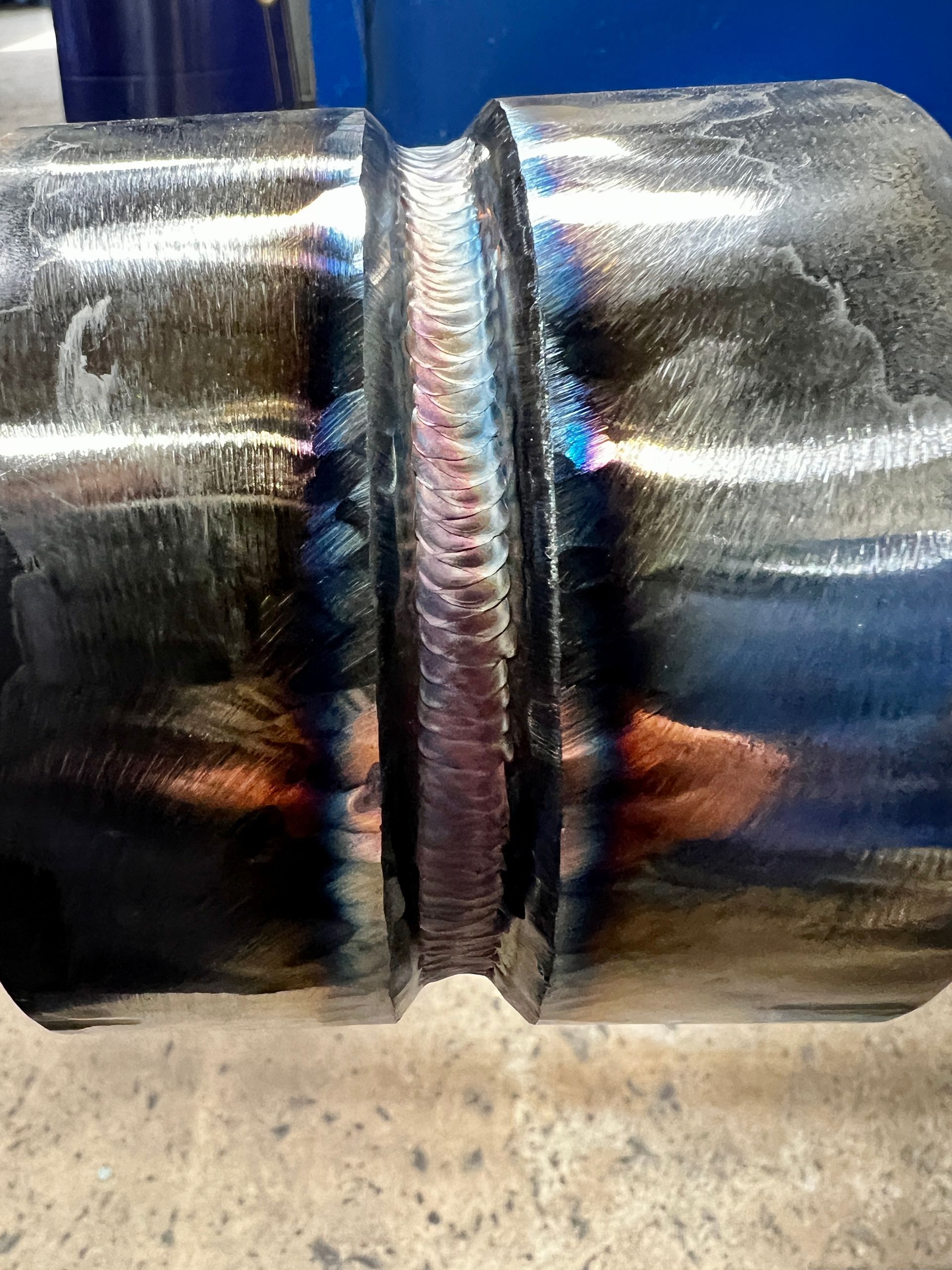

The workflow typically begins with an assessment of the metal components, project scope, and specific fabrication requirements. Once evaluated, the welding team utilizes techniques such as MIG, TIG, and stick welding to achieve secure and lasting joins. Metal pieces may be cut, bent, or assembled using precision tools, ensuring proper alignment and structural integrity. Fabrication may include brackets, frames, or specialized components tailored to exact specifications.

On-site welding allows for rapid implementation and minimal disruption, avoiding the need to transport large metal pieces to a workshop. Safety, material selection, and adherence to metalwork standards are critical throughout the process, ensuring long-lasting results that meet project demands. Skilled welders also perform detailed inspections and adjustments during fabrication to guarantee consistency, quality, and compliance with project requirements. This approach allows for efficient, high-quality metalwork that adapts to various environments and applications.

Distinctive Features of Our Mobile Welding Services

These features set Premier Arc Services apart by combining mobility, flexibility, and skill to deliver practical, high-quality welding and fabrication solutions. The importance lies in minimizing delays, maintaining material integrity, and providing adaptable metalwork options tailored to each project.

- 🔧Comprehensive Assessment: Our team evaluates every project detail to determine the most effective welding approach.

- ⚙️Custom Metal Fabrication: Components are designed and assembled to meet unique specifications.

- 🚚On-Site Solutions: Mobile welding reduces downtime by performing work directly at the project location.

- 🔒Durable Connections: Techniques ensure strong, reliable joints for long-term performance.

- 🛠️Versatile Material Handling: Capable of working with steel, aluminum, and other metals to meet diverse needs.

Whether structural frames, brackets, or repairs, our mobile welding ensures efficiency without compromising quality. In addition, our team evaluates each project thoroughly, selecting the best welding techniques and materials to meet unique requirements, while on-site adjustments allow for quick problem-solving and precise alignment. This approach guarantees consistent, durable results that withstand wear and environmental conditions. For inquiries or scheduling, call (404) 831-4441

today.

Techniques and Workflow in Custom Fabrication

Custom fabrication at Premier Arc Services involves a multi-step process designed to handle complex metalwork efficiently. Initially, we evaluate material specifications, dimensions, and design requirements. Using advanced cutting, bending, and welding equipment, our team shapes metal into components that fit exact specifications. Each piece undergoes careful alignment and assembly to ensure structural integrity. Welding techniques like MIG, TIG, and stick are applied based on the material type and project demands.

On-site adjustments allow for rapid problem-solving, and quality checks ensure each joint meets safety and durability standards. In addition, our team coordinates all aspects of fabrication, including material sourcing, component finishing, and final inspections, to ensure each project meets timelines and quality expectations.

Continuous monitoring and workflow optimization allow Premier Arc Services

to maintain high standards while accommodating urgent project needs. By integrating mobile welding with fabrication, Premier Arc Services

provides a seamless workflow that reduces transport time, limits material handling risks, and adapts to evolving project needs. This method ensures precision, efficiency, and reliability for a wide range of metalwork applications on McDonough, MD, while maintaining strong, long-lasting results that withstand environmental and operational stress.