Heavy Equipment Welding Services Delivered Directly On-Site

Reliable on-site welding and machinery repair for all industrial needs

Mobile Welding Services: Definition and Process

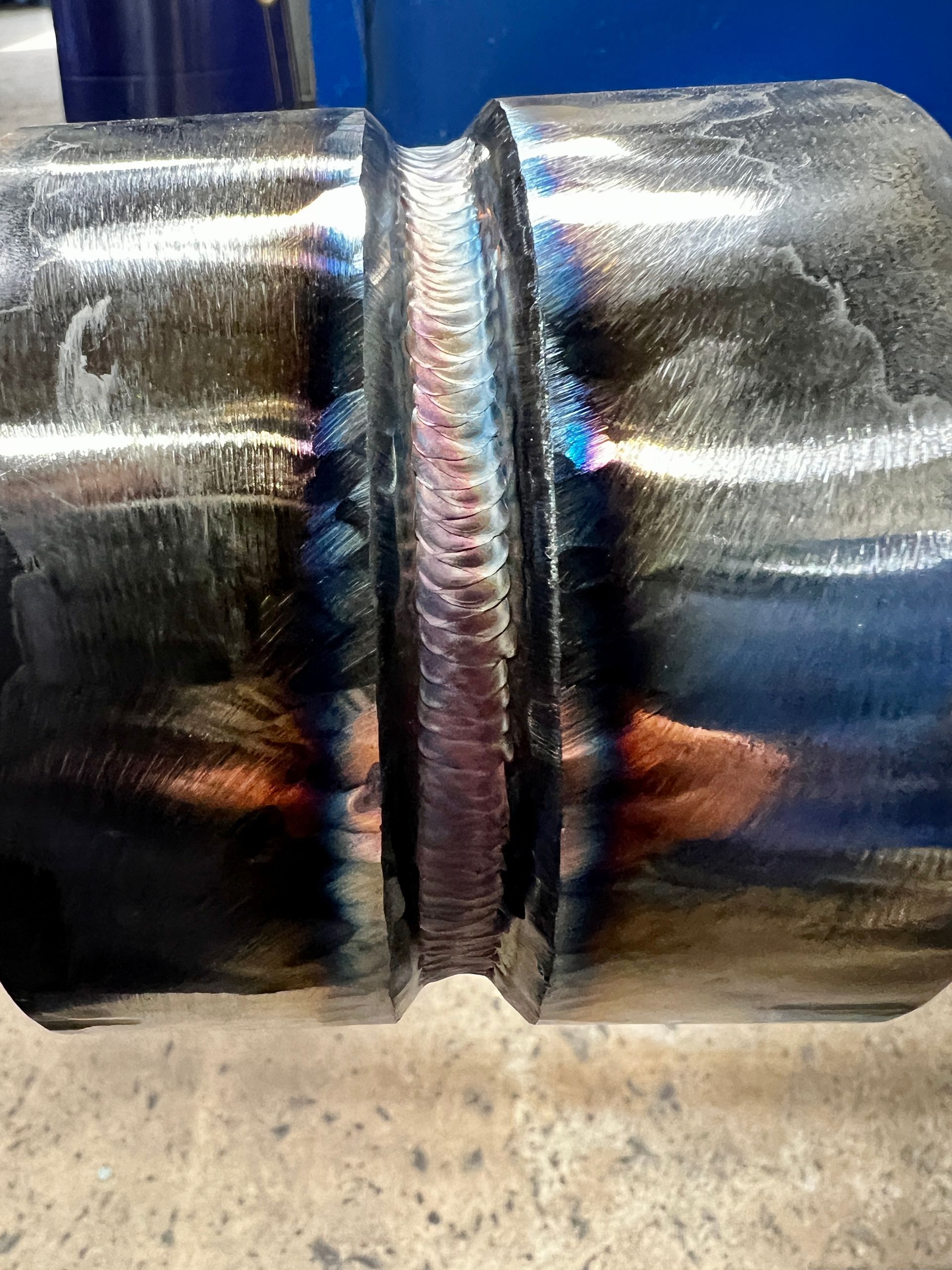

Mobile welding is the on-site repair and fabrication of metal components, structural parts, and machinery without requiring transportation to a traditional workshop. This method ensures that heavy equipment remains operational, reducing downtime and operational delays. The process begins with a thorough inspection of the damaged or worn parts to identify cracks, breaks, or areas requiring reinforcement. Technicians then select the appropriate welding method, such as MIG, TIG, or arc welding, based on the metal type and repair requirement. Once the method is determined, surfaces are prepared by cleaning, grinding, or removing rust to ensure strong adhesion.

The welding is performed on-site, allowing immediate testing and adjustments to ensure structural integrity. After welding, the equipment is inspected again, and any finishing touches or reinforcements are applied. Mobile welding also includes preventative maintenance checks, minor adjustments, and alignment corrections, ensuring that equipment operates efficiently after repairs.

By performing repairs directly at the site, technicians can address unexpected issues immediately, provide real-time solutions, and reduce overall repair costs. This process minimizes equipment downtime, increases productivity, and delivers cost-effective repair solutions without needing heavy transport or disassembly.

Advanced Equipment Support and Field Services

The strength of Premier Arc Services lies in its unique combination of mobile capability and advanced welding techniques, allowing machinery to be repaired efficiently and reliably directly on-site. This approach helps prevent costly delays, reduces equipment downtime, and eliminates the need for transporting heavy machinery.

•⚡Rapid Response: On-site welding teams arrive quickly to diagnose and repair heavy machinery, minimizing operational delays.

•⚡Comprehensive Repairs: Capable of handling structural welding, fabrication, and component replacement for various industrial equipment.

•⚡Durable Solutions: Repairs are designed to withstand heavy use and ensure long-term performance under demanding conditions.

•⚡Specialized Techniques: Utilizes MIG, TIG, and arc welding methods depending on equipment material and repair needs.

•⚡Flexible Scheduling:

Service can be performed with minimal disruption to ongoing operations and timelines.

Field teams are trained to deliver durable, long-lasting repairs while maintaining clear communication throughout every step of the process. By addressing unexpected issues immediately and performing thorough inspections, Premier Arc Services ensures equipment operates safely and consistently. At Premier Arc Services, timely, effective solutions keep machinery running smoothly and minimize interruptions to daily operations. Call (404) 831-4441 to schedule service and maintain optimal performance for all heavy equipment.

Structural Welding and Fabrication Solutions

Structural welding focuses on repairing and reinforcing critical components of heavy machinery to maintain safety and functionality. The process begins with a visual and technical inspection to assess damage or wear. Following this, the technician chooses the best welding approach, considering factors such as metal type, stress points, and load requirements.

On-site preparation involves cleaning and aligning the components to achieve precise welds. Once welding is complete, the area is cooled, cleaned, and inspected for any imperfections or weaknesses. Post-repair, the equipment is tested under normal operating conditions to verify performance. Mobile structural welding ensures repairs are immediate, preventing prolonged downtime and costly delays.

Fabrication may also include custom metal additions or modifications, designed to restore or enhance machinery functionality. Additionally, technicians may provide reinforcement to critical stress points, perform minor adjustments, and apply protective coatings to extend the lifespan of repaired components. By bringing this service directly to the site, Premier Arc Services eliminates the need for costly equipment transport, improves response times, and offers practical, reliable solutions for heavy equipment maintenance and repair in Street, MD.