On-Site Structural Welding Services in Street, MD

Dependable and On-Site Welding Services for Every Project

Understanding Structural Welding

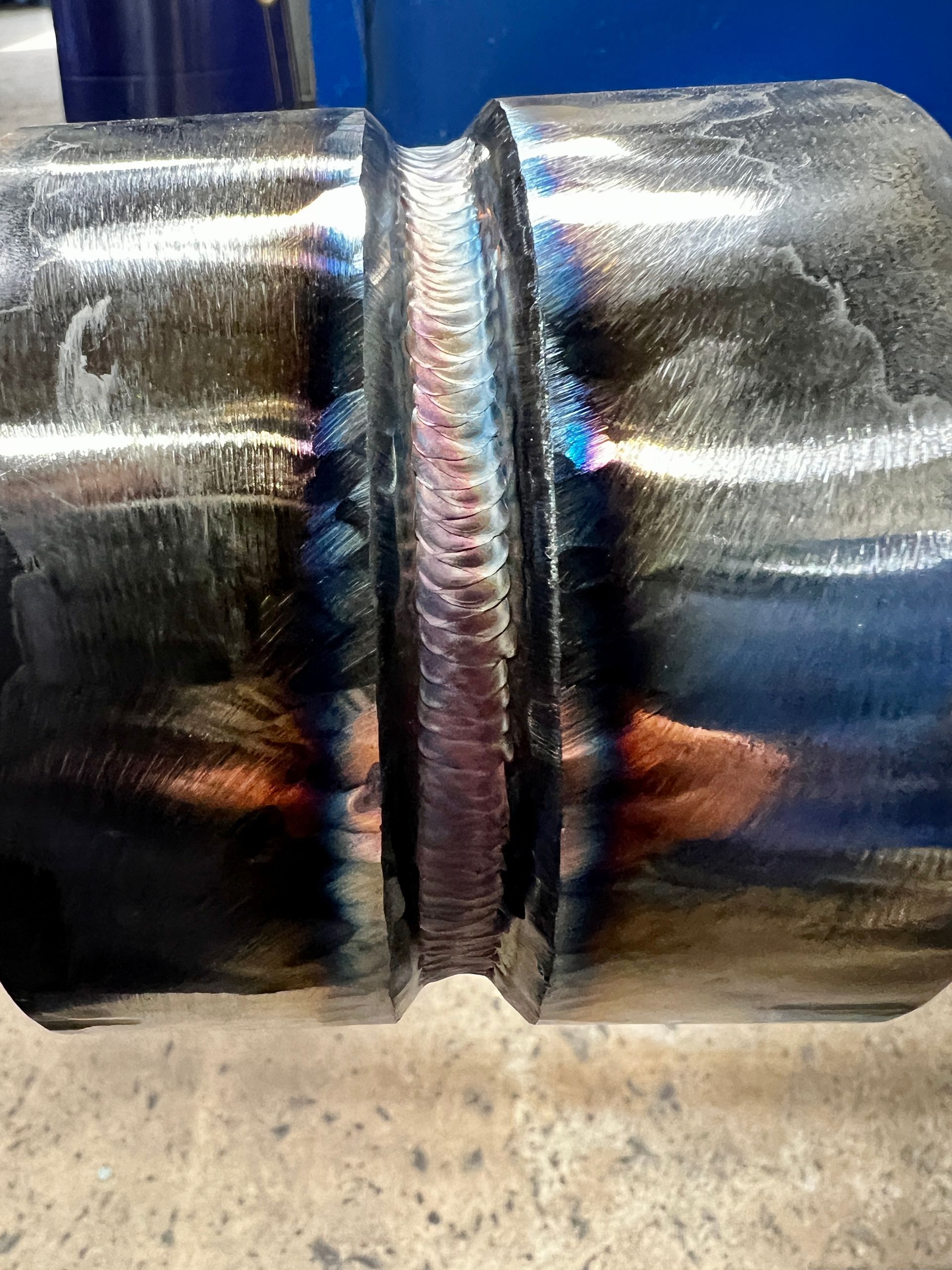

Structural welding involves joining metal components to create frameworks, supports, and other integral parts of construction and industrial projects. This process ensures the stability and longevity of the structure by combining precise techniques with durable materials. At Premier Arc Services, we approach each project with care, starting from evaluating the components and materials to planning the welding sequence.

The process begins with assessing the metal type and project requirements, followed by measuring and marking the exact spots for welding. Using specialized welding equipment, our team fuses metal pieces together, ensuring strong and reliable joints. Safety standards are strictly followed during the process to prevent any structural weaknesses. Structural welding can include various methods such as MIG, TIG, and arc welding, each chosen based on the project’s demands.

Attention to detail is crucial, from the alignment of components to the finishing of welds, as even small errors can impact the integrity of the overall structure. Our approach guarantees not only strength but also the ability to withstand environmental and operational stresses. For clients in Street, MD, Premier Arc Services delivers on-site welding services, making it convenient and efficient to complete projects without delays.

Key Features of Our Structural Welding Services

At Premier Arc Services, our mobile welding approach ensures that every structural project in Street, MD is completed efficiently and securely. We combine skill, equipment, and experience to deliver results that last.

- ⚡Custom Fabrication: We design and weld metal structures tailored to project specifications for optimal strength and durability.

- 🔧On-Site Solutions: Our team brings all necessary equipment to your location in Street, MD, reducing downtime and logistical challenges.

- 🛠Material Assessment: We evaluate and recommend suitable metals to ensure long-lasting and structurally sound results.

- 📐Precision Welding: Our methods maintain exact measurements and alignment for safe and reliable construction.

- 🔒Safety Compliance: Every project is executed with strict adherence to safety standards, protecting both people and materials.

By offering on-site services, we remove the need for transporting large metal structures, saving time and reducing potential risks. Whether it’s assembling frames, supports, or specialized metal components, our team ensures high-quality welding at every stage. Every weld we perform is carefully inspected to maintain stability and safety, providing peace of mind to clients. Our commitment to using durable materials and following industry standards guarantees long-lasting performance, while our responsive team addresses any questions or concerns promptly. For dependable structural welding services, contact us at (404) 831-4441.

Our Structural Welding Process

The structural welding process begins with a site assessment, where Premier Arc Services evaluates the project’s requirements and the materials involved. After determining the welding method, our team prepares the metal surfaces by cleaning and aligning them to ensure proper bonding. Temporary supports or jigs may be used to hold components in place during welding. Detailed measurements and careful planning are conducted to ensure accuracy at every stage. Using appropriate welding techniques, our mobile team fuses metal sections, ensuring uniform joints and strong connections.

Post-welding, each structure undergoes thorough inspection and finishing, removing any rough edges or imperfections. Additional reinforcement may be applied where necessary to improve durability. This guarantees a smooth, reliable, and long-lasting result capable of withstanding operational and environmental stresses. Our team also applies protective coatings when needed to prevent corrosion and enhance lifespan.

By performing the entire process on-site in Street, MD, Premier Arc Services

reduces transportation challenges, enhances efficiency, and maintains high safety standards throughout. Our team also documents each step to ensure quality control and provide clients with clear project updates, including photos and detailed reports for transparency.